The Biggest Problem With Latest Plastic Products, And How You Can Fix It

In case the mold material isn't wear-resistant, it is not hard to produce the cavity overwear. Plastic materials primarily made up of resins and ingredients. Plastic products have actually turned into the most essential section of plastic injection molding. To start with, the plastic product goes through high pressure, which is rather reliable at making the distinct and elaborate designs. Categorization A large variety of plastic basic materials is produced to satisfy the requirements of unique sectors of the economy. In addition, the various materials and designs can get an effect on the thickness of the item wall.

Certainly, plastic is just one of the biggest materials you'll be able to use if you've produced a fantastic concept for a product. For something, it is very flexible, with a variety of various ways to blend and match the base elements with additives to come up with the ideal item. Plastics are essentially formed into a number of shapes employing high-end practices. Usage various plastics concurrently A significant advantage of employing the injection mold technique is the ability to use a number of type of plastic at the precise moment.

In dwell stage of the plastic injection molding procedure, the plastic is left in the mold to make sure that it entirely fills the mold and after that permitted to cool to the point at which it solidifies and the preferred things is produced. The plastic positioned in the mold is location under a severe degree of pressure, that makes it far a lot easier to create the parts with excellent information. As it cools, it will strengthen into the shape of the preferred part. Obviously, the higher quality it is the greater temperature it requires to melt it. Regrettably, it was difficult to create budget-friendly, quality plastics which did not warp or break.

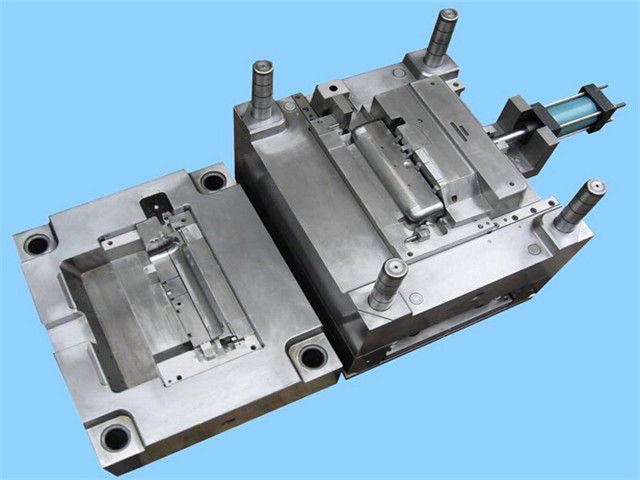

Without the most suitable pressure, the mold will not be filled, and the plastic isn't going to take the shape you desire. The injection mold can form lots of plastic parts with intricate structure, exact dimensions and great internal quality at the same time, so it's been extensively used in the production of plastic solutions. It must be installed on the injection maker. An injection mold, also described as a die or injection mold tooling, is the one most pricey product developed especially to develop a plastic part.

Plastic molding is quite a technical course of action. Plastic injection molding http://tuomorosenlund.com/duburgaqun/post-signs-you-should-7787.html is the perfect selection for all kinds of making industries at present, that's the basis of modern production service, inhabits a pivotal status in the modern-day manufacturing organisation and is understood asthe mother of market. It is a popular manufacturing process where parts are made through the injection of plastic into molds. It is among the very best alternatives for making a large range of plastic elements. Plastic injection molding is extremely useful once the plastic parts that will need to get produced are too fancy or costly to do by maker.

Injection molding is made use of to make thin-walled plastic parts for a wide variety of applications, among the most common being plastic housings. Now that you're already educated about injection molding, it is going to be easy that you understand what die casting is. Injection molding is also made use of to create numerous daily items like toothbrushes or small plastic toys. Second of all, oncethe initial injection molding is made, the treatment to make the individual parts is incredibly quick and potent.

The plastic products made by the injection molding procedure are exceptionally broad. The continuous plastic products with the same shape of the area and the mold are produced by the specific type of the mold. Plastic molding makers utilize a number of unique molding practices to create plastic components. Injection mold production works best with smaller items that can be made in one cycle. It is a way to mass-produce items and product elements for various markets.

The process of making a mold starts on an engineering table with the concept that consists of the most effective measurements and variety of cavities for any specific job. Plastic injection moulding procedure is simply among them. The procedure for Injection Moulding Manufacturers needs the usage of an injection moulding device, raw plastic material, and a mold.

The injection molding procedure needs utilizing an injection molding machine, raw plastic product, and a mold. It is a typical manufacturing technique of plastic. It is generally just appropriate for the production of hot and plastic products. It is among the most versatile production techniques in the plastic production market. The entire process of plastic injection molding utilizes a fantastic deal of electrical power.