How To Use เคเบิ้ล. What You Have To Know

Seal bags and sacks firmly with our flexible cable ties. cable ties create a safe seal on bags and sacks to secure the contents during shipping or storage. They're likewise ideal for bundling together loose parts or products and make electrical wiring and cabling more manageable.

Where To Order เคเบิ้ลไทร์. What You Have To Know

For sealing heavy bags and hessian sacks, select our strong galvanised wire tires that withstand rust and are ideal for long-lasting storage. If you need to produce an irreversible seal on polythene bags, we likewise stock a wide variety of self- locking cable ties. These include coloured ties for colour-coding items and recyclable ties that can be quickly opened and re-sealed. Desire a faster way to protect bundles? Ask our specialists about our efficient bundler sets that tie and cut in one go. We have a great variety of high quality strong cable ties readily available in a กุ้งมาโมแครป Prolock large range of sizes. cable ties can be utilized in a wide variety of applications and be available in both black and natural colours.

Working With Cable Tie. Read This First

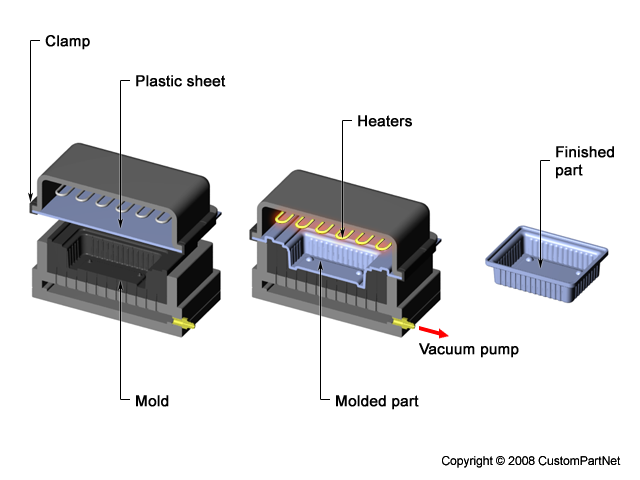

cable ties are made in an injection moulding machine, gotten rid of through a lateral, fast removal station and put on a cooling track. The sprue is separated, the cable ties are arranged in a bundled state and then fed into a provided, vertical bag forming, filling and sealing machine while being counted.

Obstacles:

The primary focus when designing the system depends on process security, speed and optimising the space available.

Removal time: max. 1 sec.

three lengths: 160, 200 and 250 mm

Any 50 cavities out of 56 are constantly and arbitrarily used (The system for this is universally construable).

Where To Order เคเบิ้ลไทร์ ราคา. cable tie ขนาด https://prolock-electric.com/ Read First

Technical solution:.

A PSA basic dealing with system with the proper grippers is utilized to eliminate the cable ties from the injection moulding device. The subsequent cooling track consists of six cooling plates as a flowing system. A cutting station with a vertical cut and suitable cutting unit is integrated at the end of the cooling track. Bundling is then done via a pushing action into the funnel. The packages are then subsequently fed to the packaging maker using a PSA basic pick-and-place robot.

Thailand สาย Cable. Read First

Production process:.

The cable tie tree is taken by the vertically-positioned gripper suction plate, the opened tool is tested and deserted.

Cooling track (6 cooling areas with 5 cooling plates, cooling time: 30 sec.): The tree is rotated into the horizontally-positioned collection cooling plate.

Cutting station (part of the 6th cooling plate) with a vertical blade stamping machine.

Binding Station: Collection system with turning system and two feeders placed on leading and on the bottom for heads If the variety of units reaches 100, the bundling gripper gathers the bundle, takes it, positions itself over the inlet for the vertical packaging maker and awaits the fast opening release. After leaving the package gripper, filling commences anew.

Test Parts: A set can be removed on demand from the cooling track and placed into the protective real estate utilizing the testing tray.

Start-up and Faulty Parts: Start-up and faulty parts are diigo.com/profile/prolockcabletie dropped from the tool on need and disposed of utilizing a slide to the operator side.

15 Things Your Boss Wishes You Knew About Red Cable Ties 200mm

Tools for Store Electrics

Store electrics, more than any other position, spend a lot of time doing the exact same thing over and over once again. Stripping, snipping, crimping, soldering and so on. You'll find that you'll want all of your regular tools as an electrical (see Basic Electric Tools) and you'll also desire some to make these repetitive tasks much faster, much easier and less strenuous. Add these tools to your kit and do not forget to charge for a package rental!

My Favorite Tools

Katapult Wire Stripper

I have wire stripers, I have lots of types of wire strippers, on set, I normally simply get my blade and have at it-- however these young puppies are a game changer.

Tacklife USB Rechargeable Screwdriver

This tool is so useful, I wish it included a pouch. Handy for all sorts of things, but important when it pertains to making a lot of Hubbells or duplexes. Not so fantastic for drilling holes.

8-Inch Diagonal Cutters

I likewise have a http://tuomorosenlund.com/carmaic0ys/post-things-most-people-21323.html pear of dikes I carry in my set pouch, however I usually utilize them for snipping zip ties. You'll want a great solid pair to tackle bigger gauge wires.

Ratcheting Crimper

It takes a lot of strength solid crimp and really rotten to need to open something up once again because a crimp didn't hold.

High Take Advantage Of Cable Cutter

Cuts through SJ 10/4 like butter! and 12/3 and 14/2 and what ever other multi-conductor cable you happen upon.

Cable Television Jacket Stripper Removal

And while we are on cable television, here is a tool you never ever understood you required but are so pleased it exists. A jacket stripper! Sick of cutting cable television coats with your utility knife just to nip into the insulation of among the conductors? Well, here you go.

Heat Glue Weapon

Also handy for making that salvaged white wine cork board, bottle cap magnets, and popsicle stick pencil holder you have have been imagining for years.

Soldering Iron

I like this package since it features a brass idea cleaner instead of a sponge. It it comes in a transparent real estate, how cool is that?

Fish Tape

Fish tape, for threading through avenue, drop ceilings, and over the grid from difficult to reach areas.

Rotary Tool Package

It is not a Dremel, but it is $20 and does the task quite well for those odd times you need to slash off a bolt or etch your name in your great brand-new tools!

Security Bit Set

Health centers, schools, government structures, jail cells ... you get the concept

Heat Gun Set

Heat shrink!! Yeah!!

Fish Sticks

Helpful for dealing with area in property locations. Quite a bit much easier to control than a fish tape if you are digging around behind sheet rock trying to get to an outlet.

The Worst Videos Of All Time About Low Profile Head Cable Ties

Desk Grommets are fantastic tool for Wire Management as it manages many wires without disturbing the appeal of the place, it is used. Grommet is actually a ring inserted into any surface through a hole so that wires can be passed through it. They can be made from plastic, rubber or metals and the surface can be anything like wood, glass, flooring or fabric product. They come with collars on their both sides for grip from both sides of the surface on which it is inserted. Normal examples of grommets can be discovered in our shoes or material where it is used to enhance the hole made in leather or material, they are smaller in sizes also called as eyelets.

In Wire Management Desk Grommet has much larger role to play when cable televisions of different type has to be travelled through one side to other side of the surface. It satisfies like protecting the cable televisions in addition to handling many wires to come through aDesk Grommet single outlets making the installation, operation and troubleshooting extremely hassle-free. The most common example of this can be discovered as Desk Grommets which are used on our working computer system table where all the electrical wires, information cable televisions, and telecommunication wires coming from the CPU linking to gadgets placed on the table top. Without grommets it provides extremely messy appearance of loose wires coming from behind the table and likewise they threaten to handle.

When hole is made through the surface area, there will be sharp edges which can spoil the cable television and wire as the insulation can be harmed due to abrasion if wires are passed though it. Grommets supply security to cables going through it as it covers all the sharp edges of the hole made on the surface area. Plastic or plastic coated metals are used for grommets making to shield the outer surface area of wires and cable televisions from any physical damages. There are many kinds of desk grommets and are typically molded, offered in different sizes and shapes for different type of Cable Management.

Molded Strip GrommetThere are special type of strip grommet which can be used to produce any shape by own. Desk Grommets are most utilized kind of grommets in furniture not only for dealing with computer system cables and wires rather they can be used for any other electrical and electronic equipments. Desk Grommets includes a case which enters into the hole and one adjustable cover which is utilized to cover the hole. The cover is kept adjustable to accommodate the area to be covered left after used cables.

Various shapes readily available in market resemble Round shaped and oval shaped and product utilized is normally plastic or epoxy covered metal. For wire management not only desk grommets are used however likewise Floor Gain access to grommets are offered for managing wires which are coming out from the flooring. They are specifically made as low profile to provide a smooth surface matching to floor with turning kind of cover to secure the wires.

There is some advanced kind of grommets like Power Tap Grommets and Retractable Power and Interaction CenterTilt N Plug Grommet which features some sockets formed in it making it easy and fast to link any wires through it. Power Tap grommets featured power sockets and Ethernet or USB socket formed in it making it prepared to utilize and a more flexible kind of connection where there can be momentary connections are required. Retractable grommets are outstanding wire managers, created vertically and can be retracted completely inside the table hiding power and information cable televisions. The finest part of these kinds of grommets is that they are easy to https://andyiibb897.shutterfly.com/26 set up as an unit and if a standard hole exists in the surface area then no skilled individual is needed for its installation.

How Technology Is Changing How We Treat Steel Cable Tie Tensioner

Metal Cable Television Seals

Metal Cable Seals|C-TPAT Cable Seals|High Security Cable Seals

[670-] Metal cable seals use a more easy to use and versatile security solution than bolt seals. Cable television lock seals are much easier to cut, though open lock with เคเบิ้ลไทร์ they still need cable television cutters or bolt cutters to get rid of, and the cable will fray when cut. These metal cable seals likewise feature laser-engraved sequential numbering as an extra tamper deterrent.

Since cable television lock seals form a complete loop when set up, they can be utilized to seal lots of types of latches that bolt seals can not. For a bolt seal to be effective, the lock hole must fit within a really particular variety of sizes; cable lock seals are efficient in any latch hole that they can fit through.

The strength of a cable seal is proportionate to the thickness of the Check over here metal cable used. Thicker cables are more powerful, along with more hard to cut through. In general, you will wish to use the tiniest cable lock seal that is appropriate for your application, as smaller cable television seals use less product and have a likewise lower price point.

If your application requires C-TPAT cable seals, our 3.5 mm cable lock seals are C-TPAT authorized. (See below to find out more.).

What are C-TPAT Cable Television Seals?

C-TPAT (Customs-Trade Partnership Against Terrorism) was launched in November 2001 by United States Customs and Border Protection. A voluntary supply chain security program, C-TPAT focuses on protecting the international trade http://goqinfo.com/drianail1r/post-how-to-master-19877.html industry against terrorism by enhancing supply chain security. This program asks participants to make sure the stability of their security practices and verify those of all partners in their supply chain.

C-TPAT cable television seals have been evaluated and approved to ISO 17712 standards for "high security" mechanical seals. These cable television lock seals are authorized for global shipping per C-TPAT policies.

Contact Supply Plaza for additional information on our C-TPAT compliant items. We also offer C-TPAT compliant bolt seals.

15 Gifts For The Plastic Cable Tie Mounts Lover In Your Life

Zip ties on light posts

Today's wonderful usage of the zip tie comes from the streets of New York city, where the NY Department of Transportation asked an art group to set up these art pieces on the posts of the streets of the city.

There are a lot of deep artsy meanings behind the installation, but eventually it just looks cool, it illuminates the streets with something distinct and intriguing, and it makes you wish to take interest, walk over, and touch it. This is not only a wonderful use of zip ties, however I believe we can all agree that a government company coordinating with some art types to use zip ties is just plain remarkable.

The art group the did this amazing and in-depth zip tie work is Animus Art Collective, and they refer to tying zip ties on street posts as the "flaming cactus." We can just think at how long it took them. Depends, I suppose, on how numerous people they needed to do the work. Apparently this job discussed well adequate that they have actually been asked by another group to do another 23 poles with their flaming cactus in the Hudson square area.

Zip ties are a wonderful bit of making that we utilize throughout all aspects of our life. As we have actually gone over continuously on this blog site, whether you choose you require some brand-new zip ties for an art installation, hold a cars and truck together, or even use them for (gasp!) practical uses like combining wiring or in an industrial setting, these little plastic monsters can be quite remarkable.

We've constantly questioned ... How long do zip ties last? When do they require to be replaced? Are certain colors better than others? What are options to zip ties if you DON'T want them to last forever? Fortunately, we discovered some answers!

Depending on what websites you consult, the majority of zip ties and cable television ties will have varying durability. In many cases, these ties are used by electrical wiring companies, cable business, and others to bundle together cables (obviously) and extra items. So these groups of individuals need their cable ties to last longer. Some people estimate the durability of these ties being anywhere from a minimum of 5 years to an optimum of ten years if exposed to the outside aspects. That is for high quality, black colored cable ties. When you have white cable television ties, the use tends to be much less, frequently quoted at about a year. That's a huge distinction! Other individuals use the exact same time ranges, some as much as twenty years depending on product the cable tie is constructed of and where it's used, and others noting that cable ties made from nylon and exposed to heat will speed the expiration date of these ties up quicker. When you're purchasing your ties, keep these aspects in mind.

However what if you DON'T want your electrical wiring to be looped for 10 years? Or, if you're utilizing cable television ties in a little function playing, being tied up for ten years might be quite dangerous. In those cases, quick use and re-usable cable television ties like beaded cable ties permit for several usage. Cable television ties like these made from a polyethylene material are done so with multiple usages in mind. We haven't had the ability to discover if there is a major difference in the longevity of these types of multiple-use cable ties, but if we do we'll let you know.

Either way, it's excellent to https://www.google.com know that when you use a zip tie to hold something in location, that it will be there for a while!

Don't Make This Silly Mistake With Your Raw Plastic Manufacturers

All our products can be found in all considerable supermarkets and wholesalers. All the products produced and supplied through this business are true to its reputation for an industry leader in the company. Every product is of the finest quality and is provided by an affordable cost. It's challenging to create such products as these using any other molding treatments. Compared to their virgin equivalents, recycled items use many of intangible but progressively crucial small company benefits. Needless to state, they have the tendency to be less energy extensive and often have a lower influence on the environment than their virgin equivalents. Creating items to enable reusing, repairing or re-manufacturing will result in fewer products going into the waste stream.

The organisation comprehends its clients and their requirements and delivers to their specific expectations successfully. These business likewise have actually prepared for the tighter environmental regulations that are specific to come. Some companies, clearly, promote the public interest even if they think in the worth of doing this. There is actually a service in the neighboring state of Indiana that may offer better affordable rates and more custom plastic molding options than each rotomolding plant in Ohio. It is called TerraCycle, and its goal is to take items that individuals generally consider impossible to recycle, and then utilize science to find out a method to do simply that. It's a China based business which operates through the website plastics-molding. All the industries that we cater for have their own uncommon procedure when it pertains to packaging, while it's for storage or transport.

Rotational moulding is perfect for lots of plastic retail companies which need to produce simply a number of plastic products at a moment. Injection molding is a method of conquering this ineffectiveness. Plastics are economical, lightweight and lasting materials, which might readily be moulded into a series of items which discover usage in a large choice of applications. They are one such product that can be recycled and plastic recycling is not only done by customers, however it is done by businesses also just on a bigger scale. Naturally degradable plastics have the ability to solve numerous waste-management problems, particularly for disposable product packaging which cannot be easily separated from organic waste in catering or from farming applications. Not one of the widely used plastics are biodegradable. 1 way of making foams of a number of thermoplastics is to incorporate a material that will decay to develop a gas when warmed.

Are plant can be found in the center of the Midwest, right in Indiana, making it best for carrying finished items to Ohio at cost saving expenses. As a result, the development of plastics has increased considerably over the previous 60 years. This strategy is made use of to produce plastic movies.

There are additional concerns connected with variations in the number and caliber of supply compared to virgin plastics. Furthermore, there are ecological and health concerns gotten in touch with their emissions. For the last few decades there have been a range of leading services in the Midwest that have been usingOhio rotational molding companies for the creation of there plastic items, and now there's a new option. No matter if you're prepared to obtain or offer, please talk to us today.

The extraordinary capability of the molding makes https://alexisydko454.tumblr.com/post/178511977313/from-around-the-web-20-awesome-photos-of-plastic it ideal for establishing a choice of shapes of any dimensional size. These systems likewise have the ability to separate polymer by type or grade and may also separate polyolefinic products like PP from HDPE. Quality management is important, because it permits Rubbermaid to produce items in a great deal of attractive colors as opposed to the normal black or gray containers made from recycled plastics. This treatment is used to produce plastic bottles. There are numerous processes associated with this phase, depending upon the sort of product. Our quality control processes integrate physical screening during and following production. Most of other procedures like injection molding and blow molding include tooling that can be exceptionally costly and technical to develop.

Among the essential benefits of recycling plastics is to lessen the requirement for plastics production. Reducing the total quantity of packaging used per item will reduce waste volumes. Not just does this offer lower expenses for smaller sized runs of products but in addition it can be quite effective in the manufacturing of plastic parts in huge amounts too, which might really decrease off your production costs. With time, but these expenses are certain to come down. While the rates are really low, this does not signify business consists of item quality. Thus, although greater oil prices likewise raise the rate of collection and reprocessing to some degree, recycling has gotten fairly more economically attractive.

The access to recycled products was a real problem simply a couple years back and still is when particular organisations, especially publishers, require large amounts of products to meet a tough deadline. Customizeded plastic mold services are also provided by Wuxi Glory. Our clients know that we're here in order to help them with all their plastic recycling requirements, and we 'd like to have the ability to help you.

The Biggest Problem With Latest Plastic Products, And How You Can Fix It

In case the mold material isn't wear-resistant, it is not hard to produce the cavity overwear. Plastic materials primarily made up of resins and ingredients. Plastic products have actually turned into the most essential section of plastic injection molding. To start with, the plastic product goes through high pressure, which is rather reliable at making the distinct and elaborate designs. Categorization A large variety of plastic basic materials is produced to satisfy the requirements of unique sectors of the economy. In addition, the various materials and designs can get an effect on the thickness of the item wall.

Certainly, plastic is just one of the biggest materials you'll be able to use if you've produced a fantastic concept for a product. For something, it is very flexible, with a variety of various ways to blend and match the base elements with additives to come up with the ideal item. Plastics are essentially formed into a number of shapes employing high-end practices. Usage various plastics concurrently A significant advantage of employing the injection mold technique is the ability to use a number of type of plastic at the precise moment.

In dwell stage of the plastic injection molding procedure, the plastic is left in the mold to make sure that it entirely fills the mold and after that permitted to cool to the point at which it solidifies and the preferred things is produced. The plastic positioned in the mold is location under a severe degree of pressure, that makes it far a lot easier to create the parts with excellent information. As it cools, it will strengthen into the shape of the preferred part. Obviously, the higher quality it is the greater temperature it requires to melt it. Regrettably, it was difficult to create budget-friendly, quality plastics which did not warp or break.

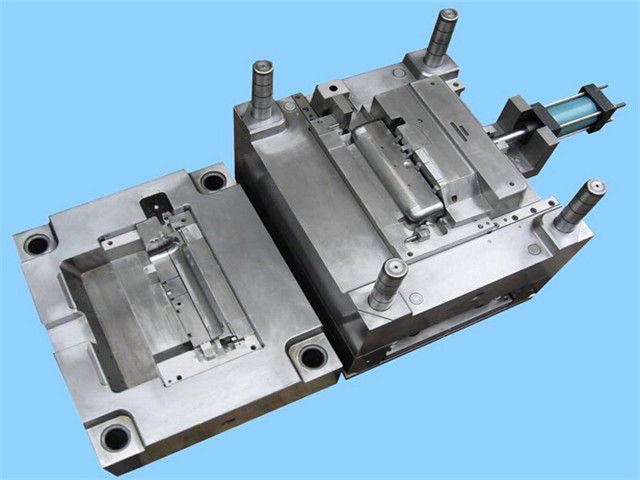

Without the most suitable pressure, the mold will not be filled, and the plastic isn't going to take the shape you desire. The injection mold can form lots of plastic parts with intricate structure, exact dimensions and great internal quality at the same time, so it's been extensively used in the production of plastic solutions. It must be installed on the injection maker. An injection mold, also described as a die or injection mold tooling, is the one most pricey product developed especially to develop a plastic part.

Plastic molding is quite a technical course of action. Plastic injection molding http://tuomorosenlund.com/duburgaqun/post-signs-you-should-7787.html is the perfect selection for all kinds of making industries at present, that's the basis of modern production service, inhabits a pivotal status in the modern-day manufacturing organisation and is understood asthe mother of market. It is a popular manufacturing process where parts are made through the injection of plastic into molds. It is among the very best alternatives for making a large range of plastic elements. Plastic injection molding is extremely useful once the plastic parts that will need to get produced are too fancy or costly to do by maker.

Injection molding is made use of to make thin-walled plastic parts for a wide variety of applications, among the most common being plastic housings. Now that you're already educated about injection molding, it is going to be easy that you understand what die casting is. Injection molding is also made use of to create numerous daily items like toothbrushes or small plastic toys. Second of all, oncethe initial injection molding is made, the treatment to make the individual parts is incredibly quick and potent.

The plastic products made by the injection molding procedure are exceptionally broad. The continuous plastic products with the same shape of the area and the mold are produced by the specific type of the mold. Plastic molding makers utilize a number of unique molding practices to create plastic components. Injection mold production works best with smaller items that can be made in one cycle. It is a way to mass-produce items and product elements for various markets.

The process of making a mold starts on an engineering table with the concept that consists of the most effective measurements and variety of cavities for any specific job. Plastic injection moulding procedure is simply among them. The procedure for Injection Moulding Manufacturers needs the usage of an injection moulding device, raw plastic material, and a mold.

The injection molding procedure needs utilizing an injection molding machine, raw plastic product, and a mold. It is a typical manufacturing technique of plastic. It is generally just appropriate for the production of hot and plastic products. It is among the most versatile production techniques in the plastic production market. The entire process of plastic injection molding utilizes a fantastic deal of electrical power.